Currency

Currency

TELEPHONE: 0208 527 6006

Mon - Fri: 9:30am - 5pm

Last order for next day delivery at 4.30pm

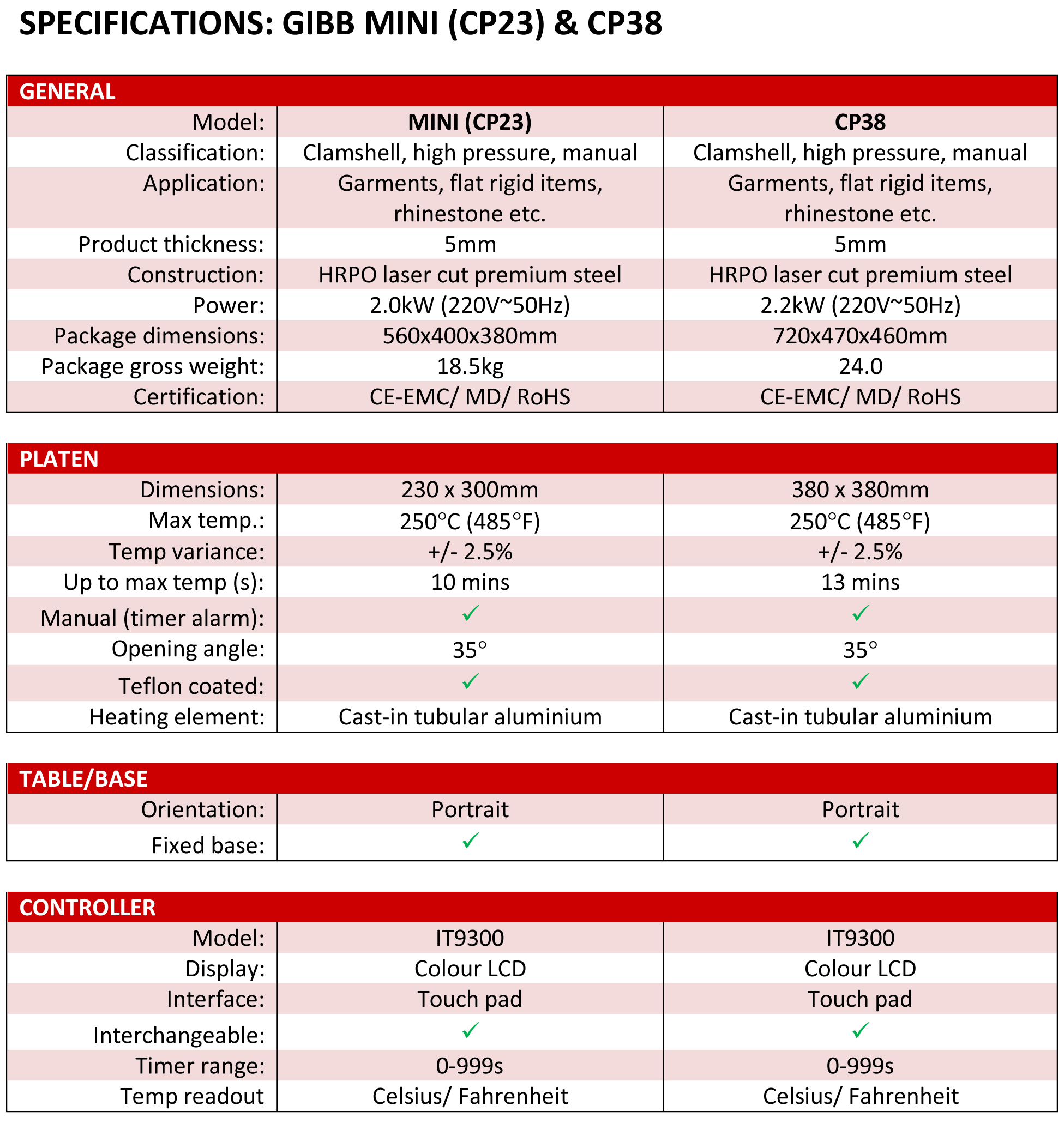

GIBB MINI CP23 high pressure heat press 230x300mm

£239.00

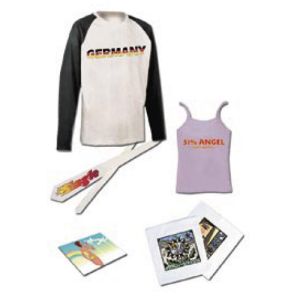

The GIBB MINI CP23 is a high-pressure manual clamshell press ideal for garments, flat items and rhinestone heat transfer

• OTC & radial pressure distribution - uniform pressure across the platen

• High watt density - uniform heat distribution with lower than 0 - 2.5% variance

• Strong & sturdy construction - HRPO laser cut premium steel chassis and frame

• Baked-on laquer coating - scratch & corrosion resistant plus it looks great

Applications: T-shirt & garments (including rhinestone), metal photo panels, signage, phone covers (2D) etc.

Availability: In stock

SKU

S6C230

The professionals' choice

Its small footprint and diverse range of applications make the GIBB Mini-Clam an ideal solution for sublimation retailers and small businesses so if you're looking for a strong and sturdily constructed high pressure clamshell press at a ridiculously low price then look no further!

Clamshell design

Unlike swing-away presses, the platen on a clamshell press opens quite literally like a clam which makes them ideal in situations where space comes at a premium. Inherent to their design clamshell presses also provide greater leverage which means that their operation requires a lot less physical effort and are thus also a little faster than swing-away presses.

High pressure

Items covered with or made of fabric (e.g. garments, mousepads, bags etc.) are soft and yielding and require greater pressure for pressing an image or design firmly and evenly into the fabric. The GIBB MINI (CP23) and GIBB CP38's strong, re-inforced frame allows for ample pressure to ensure perfectly uniform print results the same or even better than presses two or three times the price!

High watt density

It's a simple matter of physics; cast-in tubular heating elements are better at heat retention, more efficient at conducting heat evenly across a metal platen plus they are more reliable. This is the reason why the heating platens we use in all our GIBB heat presses not only heat up quicker but also boast a high watt density with heat variances as low as between 0 and 2.5%!

Uniform pressure distribution

Due to their conventional design, other clamshell presses channel applied pressure directly to the side of the platen where it pivots, diminishing as one moves further away from the hinged side. This is far from an ideal solution as it not only produces uneven print results it also limits the thickness of the items you can print.

GIBB clamshell presses however are by no means conventional and do not exhibit this problem. GIBB presses incorporate an innovative Over-The-Centre (OTC) pressure mechanism that instead channels the applied pressure from above the centre of the platen downwards perpindicular to the plain of contact. A system of vertically cast-in pressure reinforcement radiating from the centre of the platen then distributes the pressure even and uniformly over the entire platen reaching even into the sides and corners.

This innovation ensures that GIBB clamshell presses produce the most perfectly uniform print results that are even possible to achieve with a clamshell press.

Teflon-coated

Teflon is the stuff they use to coat non-stick cooking pans. Teflon coated platens are therefore not only easier to clean off blow out stains but also require no additional teflon sheets to prevent transfer materials from sticking to the upper platen.

Colour LCD with touch pad interface and on-screen icons

The cleverly designed readout and on-screen icons of the IT9300 controller makes GIBB heat presses extremely intuitive and easy to operate. The luxurious touch pad interface allows the user to enter the desired time and temperature settings quickly and accurately.

Rust and scratch prevention

All metal components, including the frame and chassis, used in the construction of GIBB heat presses are first submerged in a bath of phosphoric acid to clean off any oxidised materials and impurities followed by an electro-chemical anti-rust treatment. The frame and chassis is then coated with a baked-on rust and scratch resistant powder coating to ensure that your GIBB heat press will remain even further protected against years of rigorous use.

| Weight (kg) | 28.000000 |

|---|---|

| Features | Tile press size: 38x38cm Net Weight: 28kg Measurements: 78x48x40cm Voltage: 220v |

| Inside the Box | 1x flat press machine |

| Request Quote | No |

Write Your Own Review